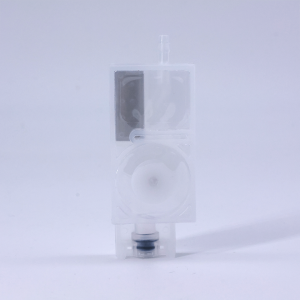

1. In the negative pressure ink supply system, the precise identification and control of the amount of ink can be realized through the control of the chip. The complete system is mainly composed of an interconnecting box body, nozzle, and adapter. The box body is respectively connected with an inlet ink tube and another outlet ink tube, the upper end of the nozzle is provided with an ink inlet and an ink overflow port, and the box body is provided with an ink level meter, used to control the ink in the box to maintain a certain amount of ink, when the ink is less than the set value will alarm, then need to add ink.

2. The whole system is composed of a set of looser check valves, which can put the nozzle and the adapter in a negative pressure state. One end is connected with the connecting hole of the adapter, and the other end is connected with a suction pipe. When the ink in the nozzle and the ink outlet tube is attracted by the negative pressure air, the ink can maintain a balanced state that will not fall, and when the inkjet head is pointed downward, the ink can be automatically pumped to fill the ink, to achieve the function of continuous printing¡£